2000㎡

Production workshop area

Production workshop area

Number of employees

Monthly output

Product category

Overall fabric adsorption, computer intelligent control technology, accurate cutting size and full monitoring of the cutting operation to ensure cutting accuracy. Identify drawing documents with 0 errors, and batch cutting ensures shipping efficiency.

Photosensitive plate making, screen printing, clear and firm printing patterns, which can meet customized printing of different colors.

The UV printing method we developed can meet the needs of multi-color integrated printing, gradient color printing, and large-area batch printing.

skilled sewing skills, multi-person collaboration mode, and efficient process. Multi-layer sewing thread reinforcement ensures the sealing and stability of the product structure.

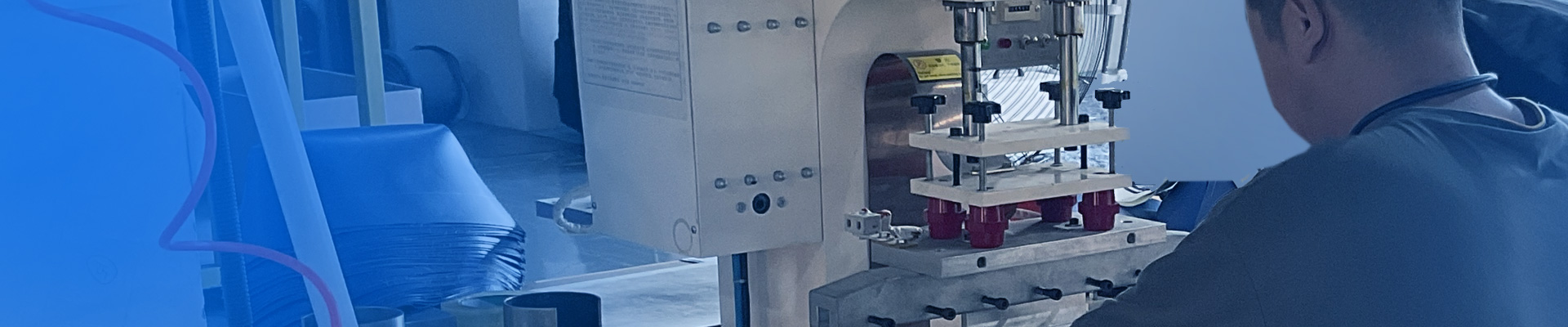

The welding temperature is stable, the welding joint is strong and beautiful, and the production efficiency is high. We have different types of high-frequency machines corresponding to different welding areas, and the process is exquisite and stable.

The design of heating welding is highly scalable and can heat and complete welding in areas that are difficult to weld. The introduction and use of hot air fans can meet the welding processes of oxygen chambers of different shapes.

Product installation and debugging, final quality inspection, and packaging into final products

Have an experienced and skilled team. Our employees know how to work together, have the expertise, and are constantly trained to keep up with the latest developments in the industry.

Our factory is committed to continuous innovation and research and development of new products and technologies. We cooperate with major research institutions and experts to maintain cutting-edge contact with the industry and apply the latest technology to the manufacturing of our soft hyperbaric oxygen chambers.

Our factory attaches great importance to customer needs and satisfaction. We adhere to the principle of customer first, provide personalized solutions, and respond to customer feedback and requirements in a timely manner.

Oxy Spaces has the latest production technology, works on the principle of 24-hour production, and works with the highest efficiency. With global market knowledge, we provide customer-oriented production solutions to meet your hyperbaric chamber expectations.

We have an advanced R&D center and strict quality control processes, which are our standards for producing the highest quality products using state-of-the-art production facilities.

All products we produce use healthy raw materials that do not harm nature. The health of our employees and customers is of utmost importance to us.

In order to extend the service life of production equipment, we perform maintenance within fixed periods to ensure normal operation. In addition, our employees are professionally trained to perform production tasks according to our operating standards.